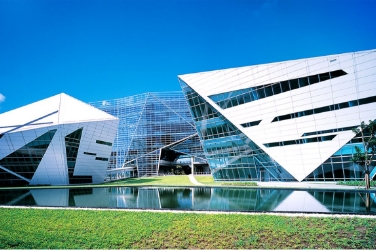

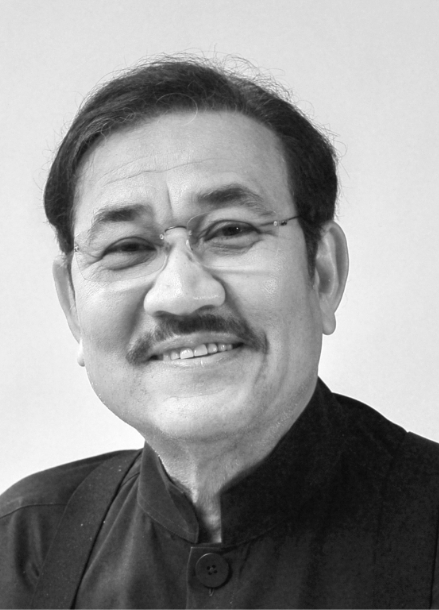

In 1980, Prabhakorn received his Bachelor of Architecture degree from Chulalongkorn University. He continued his education at the Catholic University of America in Washington DC, where he graduated with a Master of Architecture degree in 1984. Whilst in Washington DC, Prabhakorn worked at Robert Schwinn & Associates in Maryland before returning to Thailand and joining A49 in 1985. At A49, he has been responsible for a wide range of projects ranging from mega complexes and high-rise buildings to houses. Most of these are located in Thailand, whilst others are located in other countries in the region, including: China, Malaysia, Singapore and Vietnam. His work has also extended outside that region, for example, to the United Arab Emirates and India. All add breadth to the A49 portfolio of work. His main role has been to establish major policies, design concepts and strategic planning initiatives. He was appointed as President of Architects49 Phuket in 2005 and President of Architects49 International in 2006.

Prabhakorn actively served the Association of Siamese Architects (ASA) as its Head of Public Relations from 1992 to 1994, as its Vice President of Foreign Affairs from 1995 to 1997, and as the President of ASA during 2002-2004. He has also participated in many subcommittees for both the ASA and the Architect Council of Thailand (ACT). He is an active Council Member of the ACT, with his present duties for them extending into 2018. He has been an Honorary member of the Japan Institute of Architects (JIA) since 2003.

Prabhakorn has been a key member of A49 since its foundation, and has the honour of being trusted by Nithi Sthapitanonda (the Founder of A49) to be President and Managing Director of 49Group.

In 1980, Prabhakorn received his Bachelor of Architecture degree from Chulalongkorn University. He continued his education at the Catholic University of America in Washington DC, where he graduated with a Master of Architecture degree in 1984. Whilst in Washington DC, Prabhakorn worked at Robert Schwinn & Associates in Maryland before returning to Thailand and joining A49 in 1985. At A49, he has been responsible for a wide range of projects ranging from mega complexes and high-rise buildings to houses. Most of these are located in Thailand, whilst others are located in other countries in the region, including: China, Malaysia, Singapore and Vietnam. His work has also extended outside that region, for example, to the United Arab Emirates and India. All add breadth to the A49 portfolio of work. His main role has been to establish major policies, design concepts and strategic planning initiatives. He was appointed as President of Architects49 Phuket in 2005 and President of Architects49 International in 2006.

Prabhakorn actively served the Association of Siamese Architects (ASA) as its Head of Public Relations from 1992 to 1994, as its Vice President of Foreign Affairs from 1995 to 1997, and as the President of ASA during 2002-2004. He has also participated in many subcommittees for both the ASA and the Architect Council of Thailand (ACT). He is an active Council Member of the ACT, with his present duties for them extending into 2018. He has been an Honorary member of the Japan Institute of Architects (JIA) since 2003.

Prabhakorn has been a key member of A49 since its foundation, and has the honour of being trusted by Nithi Sthapitanonda (the Founder of A49) to be President and Managing Director of 49Group.

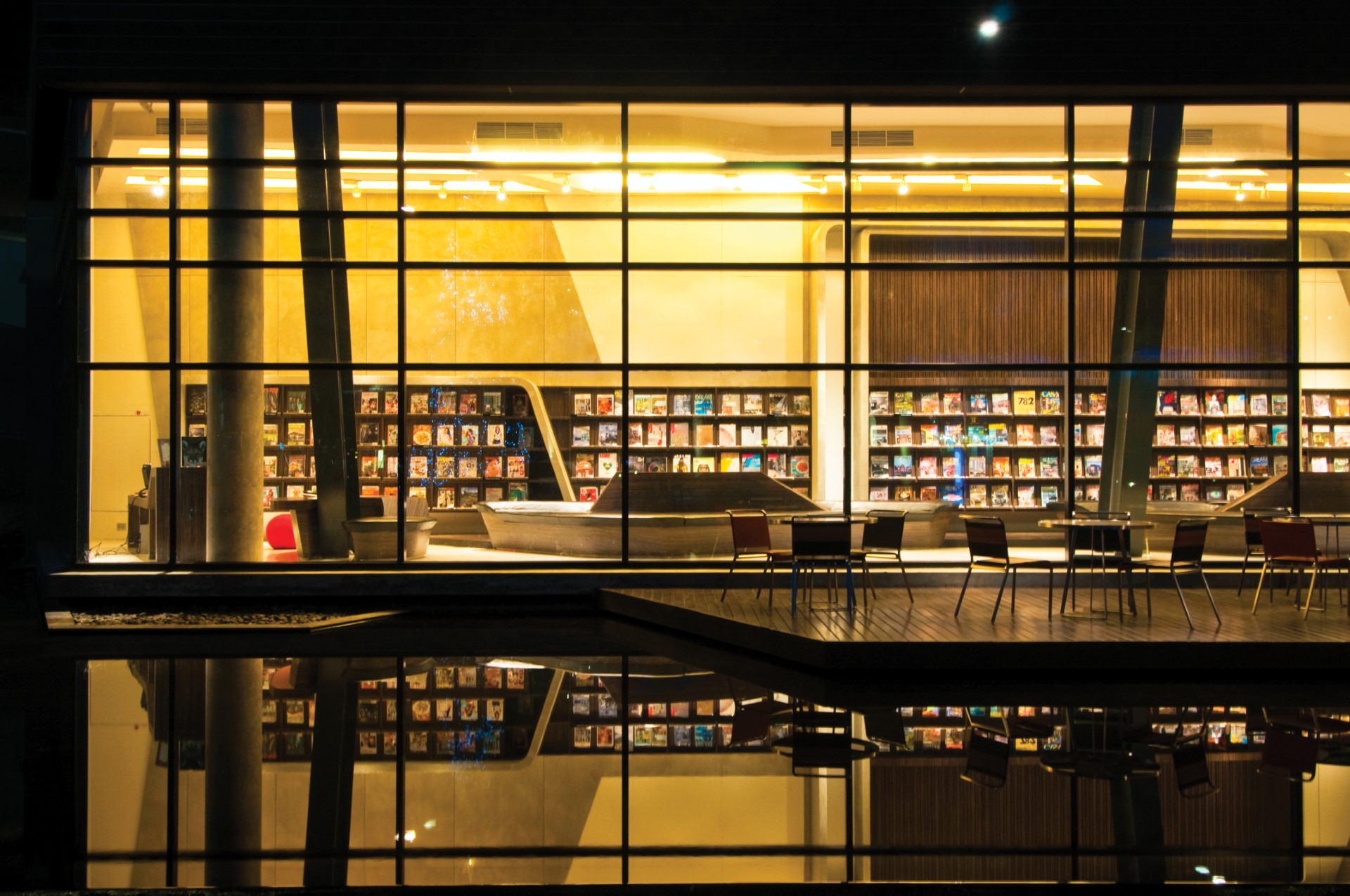

In collaboration with Landscape Architects 49, we have extensive experience in master planning and urban design. We have worked for both government and private sectors from large urban development to planning of new university campus.